BlinkM Cylon mkII

/For Maker Faire this year I made a second version of my BlinkM Cylon: BlinkM Cylon mkII. This is not a very cost-effective way of getting a Cylon effect. It however is a good way of showing how to wire up multiple BlinkMs with a long cable, using our new WireM cabling kit for BlinkM. And unlike normal Cylon circuits, this has full RGB color effects and gradual fading.

Here’s a quick video showing it in action.

BlinkM Cylon mkII consists of:

- 13 BlinkMs (one for each of the tribes of Kobol)

- one WireM cabling kit for BlinkM, consisting of IDC connectors & ribbon cable

- an Arduino

- two 4.7k resistors

- a single push-button

- 9VDC wall wart to power it all.

- laser cut acrylic enclosure

Below are all the files needed to recreate your own BlinkM Cylon. Click any of the images for larger versions.

Firmware

The sketch that runs on the Arduino is pretty straight-forward. It’s a minor update to the existing BlinkMCylon sketch. You can find it on the blinkm-examples Google code project. The files are:

- BlinkMCylon.pde – the actual sketch

- BlinkM_funcs.h – BlinkM library

Circuit

The circuit is 13 BlinkMs and one Arduino hooked up to a single 4-wire I2C bus (Gnd/+5V/SDA/SCL). Like this:

Because the I2C bus is fairly long, two pull-up resistors on SDA (aka ‘d’ on BlinkM) and SCL (aka ‘c’) are added.

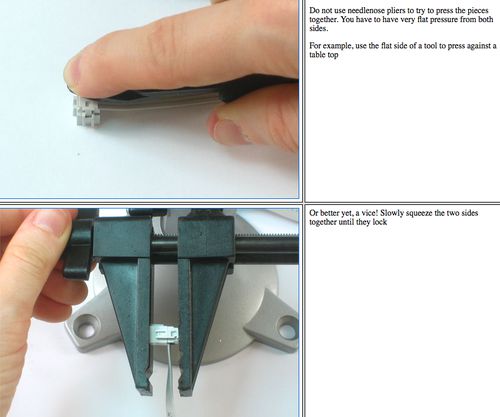

To assemble the cable, position the IDC socket connectors where you want them, and crimp them together. For the BlinkM Cylon, the connectors are spaced about 3″ apart. For info on how to crimp the connectors, see the bottom of the Adafruit USBtinyISP page, here’s a highlight

Enclosure

The enclosure is made from laser-cut acrylic. It’s mostly clear 1/8″ (3mm) acrylic with the diffuser made from 1/16″ (1.5mm) acrylic ceiling fixture diffuser sheet. The plans for cutting your own of these are available in EPS and CDR format from Thingiverse, they look like:

To secure the BlinkMs, little BlinkM holders were created. Each BlinkM is hot-glue tacked to the holder and the holder is snapped into the base plate. The entire laser cut assembly is meant to snap together. To keep it together use rubber bands, some dabs of super glue, or proper acrylic cement to make a permanent installation.